Chlorinated solvent vapors can have serious detrimental effects on human health, especially for workers dealing with waste materials and industrial processes. Both the US Occupational Safety and Health Administration (OSHA) and the American Conference of Governmental Industrial Hygienists (ACGIH) publish Permissible Exposure Limits (OSHA) and Threshold Limit Values (ACGIH) for a full range of organic compounds. Three types of PEL/TLVs are defined: time-weighted average – TWA (typically on the basis of an 8 hour workday), short-term exposure limit – STEL (spot exposure for 15 minutes), and ceiling limit – C (maximum exposure at any time). Values for TLVs vary due to the toxicity variations of differing chemical compounds.

Several examples from ACGIH/OSHA are listed below:

| Chemical | ACGIH TLV-TWA | ACGIH TLV-STEL | OSHA PEL-C |

| Carbon Tetrachloride | 5 ppmV | 10 ppmV | 25 ppmV |

| 1,1,1-Trichloroethane | 350 ppmV | 450 ppmV | – |

| Chloroform | 10 ppmV | – | 50 ppmV |

| Methylene Chloride | 50 ppmV | 100 ppmV | – |

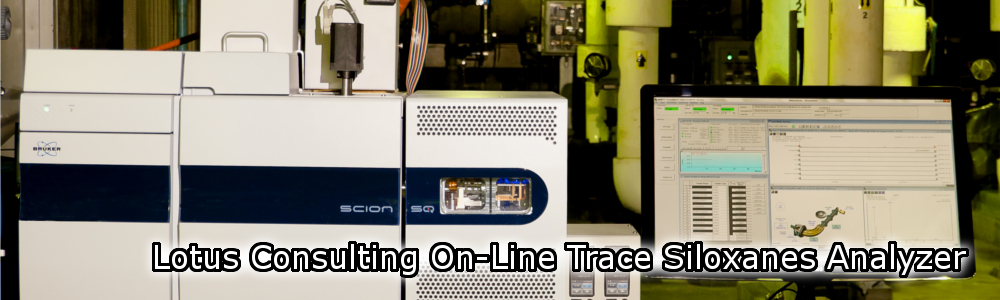

Bruker 450 GC mounted on a portable cart with supply gases on bottom shelf

Gas chromatography is the ideal analytical technique to assess many of these compounds, especially with specific detectors such as electron capture for chlorinated analytes, or photoionization for aromatics and olefins. The Lotus Threshold Alarming for Chlorinated Hydrocarbons (TACH) puts the whole system – including workstation, supply gases, and standards – on a portable cart, which allows the unit to be placed near work areas for monitoring the ambient environment.

Results are typically reported every 15-20 minutes, depending on the chromatography for the target compounds. Data is continuously collected without operator interactions, and results are automatically processed and compared to established Threshold Limit Values. When an analyte level exceeds these action limits, an alarm is triggered with flashing lights and audible horns. An automated sampler is included to allow measurements at multiple sites away from the immediate location of the instrument. Two sampling positions are reserved for a system blank and a calibration/verification mixture, and injections of each can be established at pre-selected intervals in the sampling sequence.