Many field samples do not lend themselves to direct analytical measurements in situ. The necessary instrumentation can be too cumbersome to transport into the field, or utility requirements for the measurement can be too difficult to maintain outside laboratory environs. These samples must then be collected and transported back to the laboratory. Air samples are usually collected into Tedlar bags or metal canisters for conveyance.

Tedlar bags offer the advantages of lower expense and one-time usage, and are usually quite acceptable for local sampling. However, these bags do not transport well due to their fragility, require a sample pump to fill them and are not usually reusable.

Canisters have the advantage of ruggedness during transport, especially by air. Moreover, the canister can be evacuated prior to sampling; then the sample is simply drawn into the canister without need for a pump. Canister costs mandate their reuse, and canisters must undergo a rigorous cleaning process to minimize sample carryover and cross-contamination.

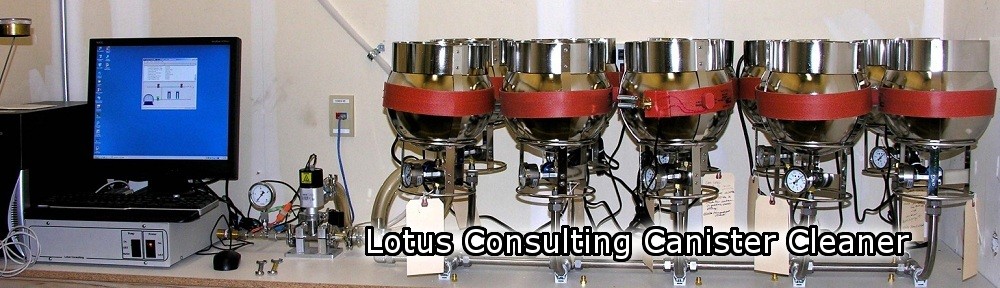

Canisters are processed by installing them onto the Canister Cleaner manifold system. This cleaner then cycles through a preselected sequence of pressurization, release to atmosphere and evacuation by vacuum. To further enhance the cleaning process, temperature can be applied to the canisters during the cycle. A runlog is generated for each sequence, documenting steps, time within each step and vacuum/pressures achieved. Canisters can be left either fully evacuated, pressurized, or at atmospheric pressure, selectable by the user. The user can also choose to print out a certificate of compliance for each canister.